Owning the UK Roadmap for Additive Manufacture for Defence

Technologies including sensors, multifunctional materials and structural parts that QinetiQ is developing for applications in land, maritime and air domains using novel materials, are increasingly relying upon AM. A few examples include next-generation armour materials, materials to mitigate against lightning strike for composites, acoustic materials for signature reduction, electromagnetic structures such as radomes and antennas, and extreme temperature metallic alloys for hypersonic applications.

Additive Manufacturing entails the manufacture of 3D objects, typically using layer-by-layer deposition of a feedstock material featuring anything from polymers through to metals or combinations using computer aided design. AM will be a key tool in speeding up the adoption of technology, reducing the time from concept to being in the user’s hand. This includes a number of specific advantages, such as lower costs, tailored and bespoke products, in-field manufacture, and disruption of supply chains.

QinetiQ has devised a series of collaborative workshops to develop an integrated ‘UK AM Roadmap for Defence’ to encapsulate the current position, identify gaps and barriers to development, and outline key areas of focus. The first of these, titled ‘Challenging the current certification and qualification methodologies for AM within the defence sector’, took place in May 2023 and introduced the approach to build a set of roadmaps with a partner network that will help define the UK position.

Dr Ryan Seabright, QinetiQ’s Lead of the AM initiative said: that we are delighted at the response from our stakeholders and partner network who have contributed immensely in launching this activity.

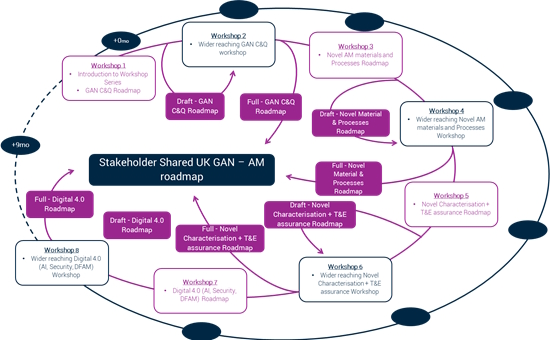

With initial roadmaps, a series of whitepapers and follow-up events planned, the schematic below details future workshops and the progression of the outputs over a nine-month period.

Here are some examples of additive manufacture produced at QinetiQ:

Additive Manufactured radome structure for electromagnetic applications

Metamaterial device for wave control produced using additive layer manufacture

4D large area printed structure for tunable applications

28/07/2023

- Sajad Haq

Recent Blogs

-

QinetiQ’s Contribution to Atlantic Bastion

08 Dec 2025

-

Driving SME Innovation for Defence

03 Dec 2025

-

Cyber Insurance: Why resilience is the only policy that always pays out

18 Nov 2025

-

Resilience, regulation, recovery – and the reality facing cyber leaders

03 Oct 2025

-

85 Years Since Fighter Command VC Flight From MOD Boscombe Down

14 Aug 2025