It is not just a case of ensuring performance and operational costs meet target objectives. The development of new materials, the scope for adopting alternative fuels and the introduction of new regulations also present new and constantly evolving challenges to the designers, builders and owners of ships and submarines.

Rising effectively to such structural and survivability engineering challenges demands a unique blend of skills, insight and dedicated resources. With over 40 years of knowledge and experience in experimental validation and with an array of market-leading tools and extensive investment research and development work in this specialist area, QinetiQ continues to lead by example.

We are trusted by defence and commercial organisations all over the world to deliver novel and bespoke solutions and exceptional outcomes that address the challenging problems of Shock, Structural Analysis, Structural Integrity and Survivability. Our services comprise comprehensive analysis and assessment, a mix of theoretical and empirical solutions and a full range of consultancy support to deliver operational and capability advantages to our clients.

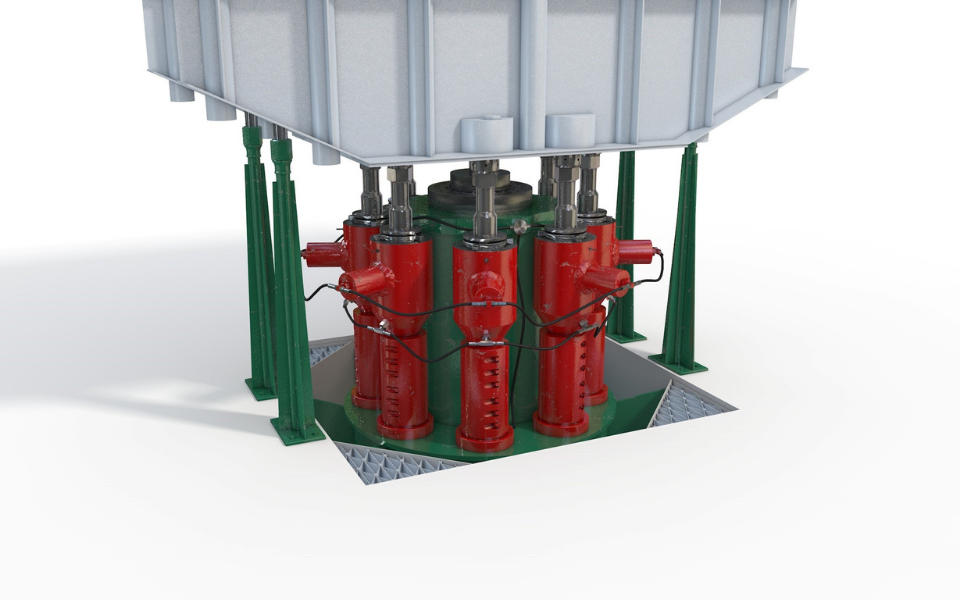

Shock

QinetiQ’s specialist dynamic shock test service provides the most representative method of equipment and system shock qualification for onboard installation.

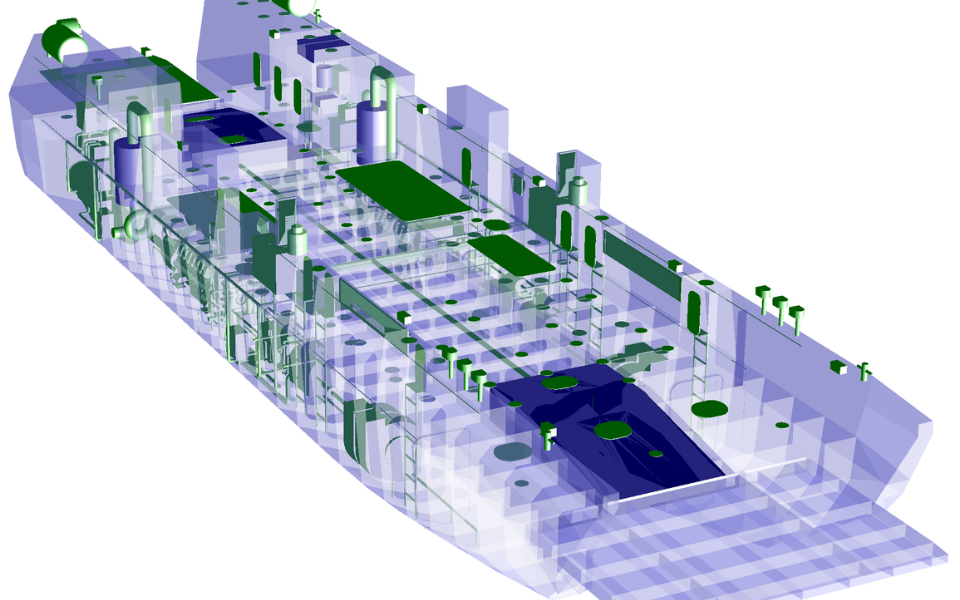

Structural Analysis

We deliver expert structural analysis advice derived from appropriate engineering hand calculations through to leading edge modelling.

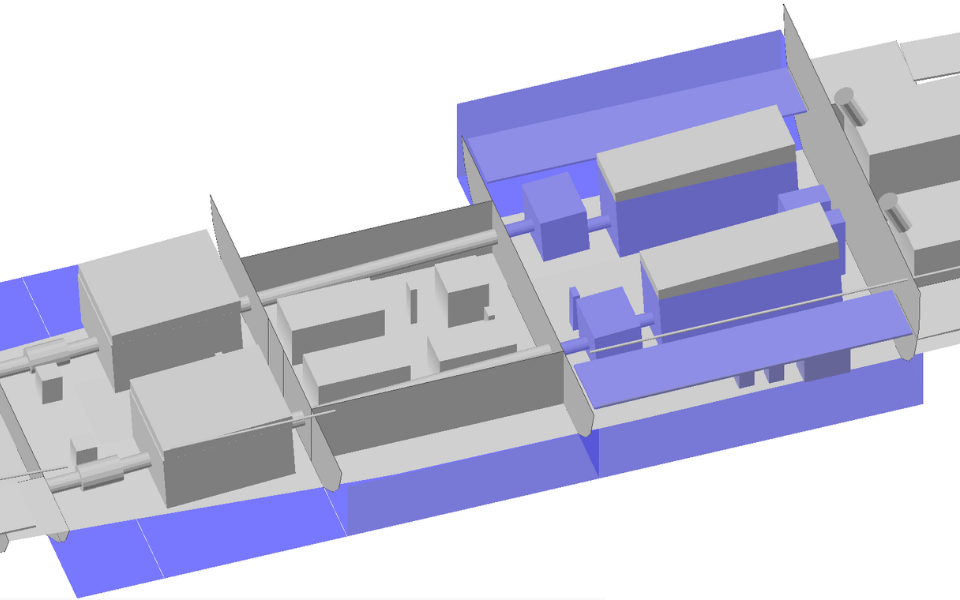

Structural Integrity

We deliver expert structural integrity advice derived from our detailed knowledge of materials, complimenting the structural assessment for both statics and dynamics whether these be thermal or shock stresses.

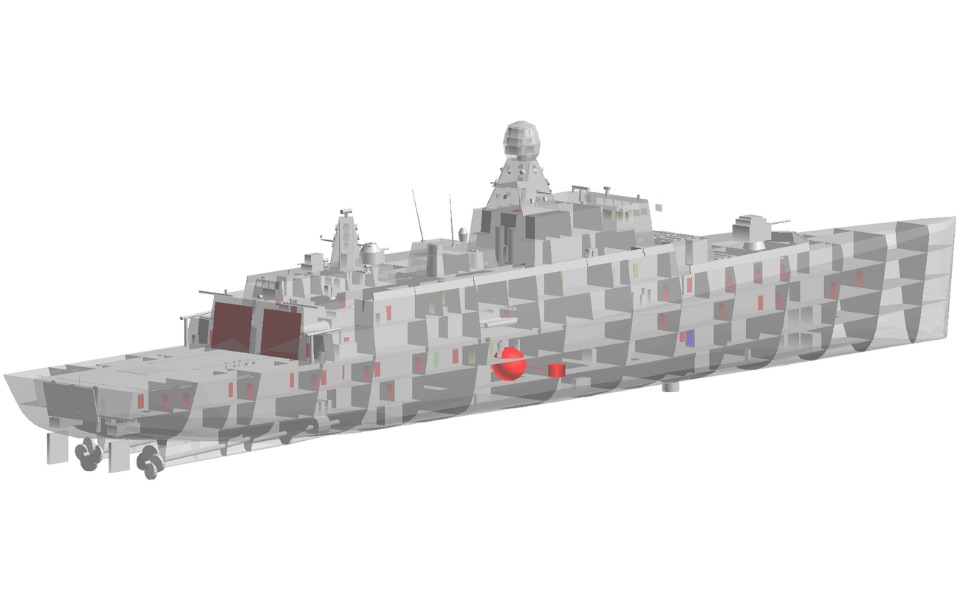

Survivability

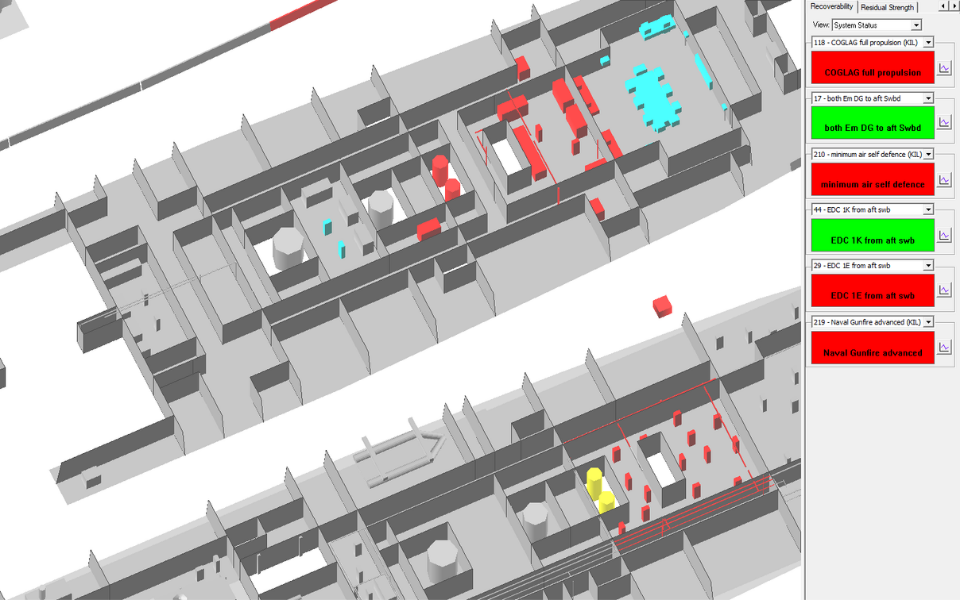

By comparing the vulnerability of a vessel against the lethality of a variety of threats using our Survive® software, QinetiQ’s experts can support critical design decisions and in-service alterations to a vessel for the environment it is intended to operate in.